Dulau

THE COMPANY’S MAIN ACTIVITIES

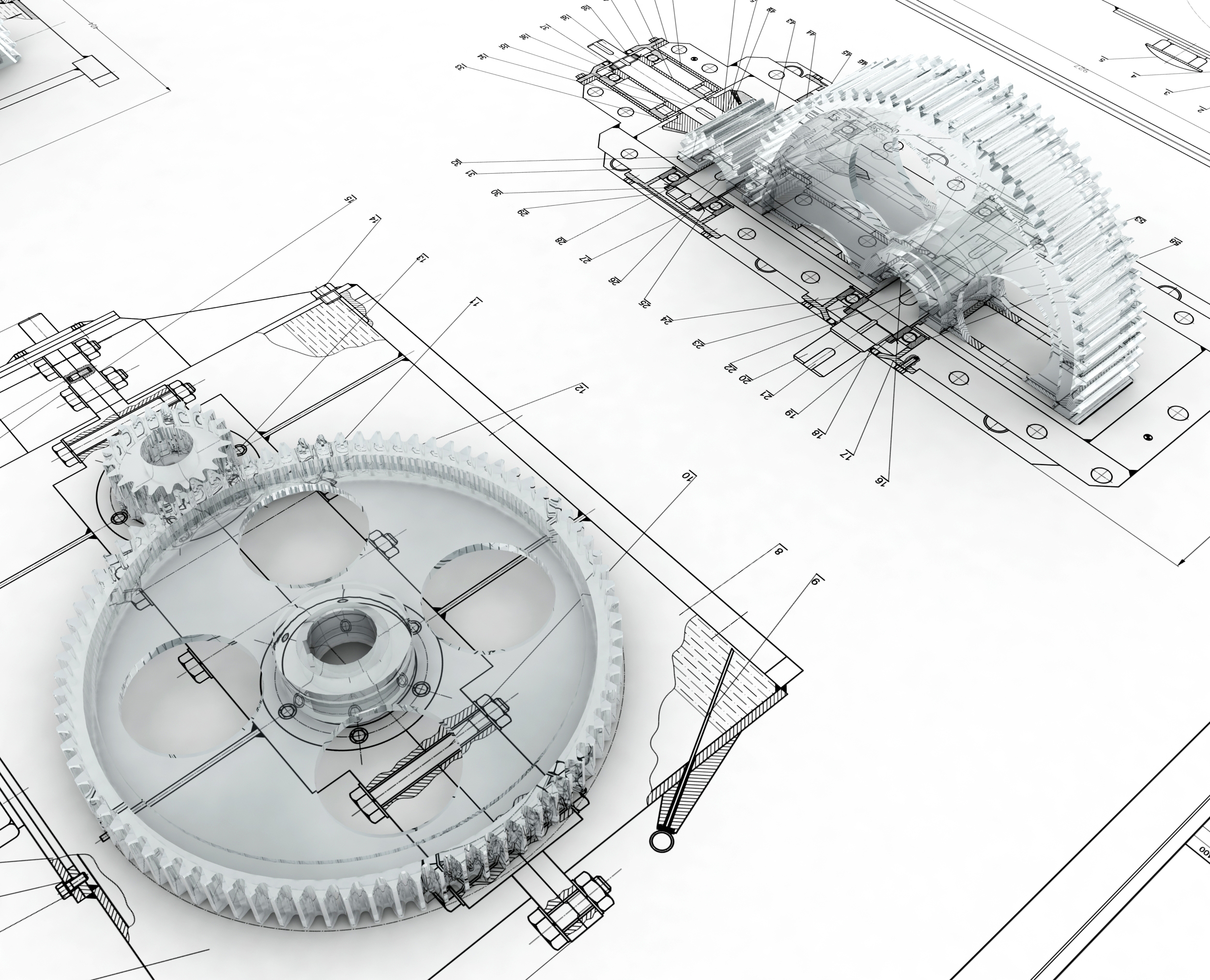

We specialise in:

- Light and semi-heavy mechanised components; unique components and series of components

- Industrial maintenance

- Assembly

- Repairing hydraulic and pneumatic cylinders.

- Construction of machinery to plan.

THE COMPANY’S PRODUCTION

Industrial mechanics machining and maintenance

THE COMPANY’S MAIN MACHINERY

We have the following machinery:

- CNC turning lathe with motorized tooling and “Y” axis with 1350 mm between points and 530 mm turning

- CNC turning lathe with 3 metres between points and 1,000 mm turning

- Conventional lathe with 3 metres between points and 800 mm turning.

- CNC turning lathe with 1.5 metres between points and 620 mm turning

- Conventional lathe with 1.5 metres between points and 500 mm turning.

- CNC boring machine, 125 diameter quill, 1-metre quill exit, 3-metre length, transversal axes and 2-metre vertical axes, 2,600 x 1,850-length table, with capacity for machining pieces of up to 5 tonnes.

- CNC milling machine, 1,860 fixed bed with longitudinal axis travel, 1,500 mm transversal axis travel and 1,250 mm vertical axis.

- Conventional milling machine with 1-metre longitudinal axis travel, 400 mm vertical axis and 500 mm transversal axis.

- Drill press for bits up to 40 mm.

- Thread cutter up to M40.

- Shaping machine

- Soldering, complete manufacture of rollers, small metallic structures, etc.

- Machinery maintenance and repairing.

- Construction and repair of hydraulic cylinders.

- Repair of pneumatic cylinders.

- Pressure set for testing cylinders up to 140 kg/cm2.

- Crane: up to 5 tonnes.

- We also have our own transport for

- pieces up to 1.5 tonnes.

CERTIFICATES AND STANDARDISATIONS

UNE-EN ISO 9001:2015 certificate

UNE-EN ISO 14001:2015 certificate

OSHAS 18001 certificate

Date

February 22, 2016